TABLE OF CONTENT

When the economy flips, resilient businesses will be the ones to emerge from the apocalypse. And building the resilience of a business is not a joke. In the face of adversity, businesses often make decisions not backed by data, ultimately leading to the downfall of the empire. As dramatic as it sounds, lack of resilience or poor resilience is not something that companies wake themselves to. It is rather a result of the organization’s culture.

Given the current volatility of the market, brands have been making “extra” measures to make sure they don’t have to tap out under bad weather, and many popular consumer brands have started to reinforce their supply chain management systems. Unlike consumers panic-buying toilet paper, companies cannot afford to make this mistake. They have to break out of their traditional product flow systems and infuse digital platforms into their infrastructure to identify areas that can be optimized.

Before we see the key features of an effective supply chain management system, let’s answer the question…

What is supply chain management?

From the procurement of raw materials to the delivery of final output to consumers- every process that aids and supports this comes under supply chain management. The flow of goods or services from the origin point to the end user is visualized as a chain with various links making that chain.

Many a time, businesses tend to use supply chain and logistics interchangeably, and they couldn’t be more wrong about it! In fact, confusing supply chain management and logistics may result in greater unaccountability and lead to increased anomalies in the inventory. Logistics is rather a part of supply chain management, and it particularly focuses on the transportation and movement of assets than anything.

Contrary to popular belief, supply chains have been a major part of human lives ever since we started trading using the barter system. However, with current innovations and technological advancements, supply chain management can identify misplaced efforts or missed opportunities much more efficiently, helping businesses to save tons of operational costs and redirect efforts towards more urgent areas. The evolution of supply chain management will further expand the scope of various players in the field.

Supply chain management process

Our industry experts at W2S Solutions identify the following 5 areas as the core processes of a supply chain management framework. As we move forward in the digital age, these 5 areas could be split into even smaller chunks, making the process even more air-tight and efficient. The supply chain management process is as follows,

- Planning

- Sourcing

- Manufacturing

- Delivery and logistics

- Returning

-

Planning

Like in any other domain, planning in supply chain management is all about coming up with a well-laid-out structure for the goods or services, or information to flow from point A to B. Additionally, planning in supply chain management helps businesses diffuse many “what if” scenarios. There are many supply chain planning software in the market that helps businesses with the process.

-

Sourcing

Though there are many types of supply chain sourcing, the most common dilemma for a company is to whether go for in-sourcing or out-sourcing. While each has its benefits, the decision should be made with a long-term view in mind. companies have to compare various factors while choosing their suppliers as it will have a direct effect on the end consumer experience. On the flip side, this is also an important area for companies to save costs. By strategically choosing their suppliers, companies can increase their profit margin among many other things.

-

Manufacturing

In simple terms, this is where the magic happens. Think of manufacturing as the common link between different operations including raw material procurement, quality check, logistics, R&D, etc. Many companies are embracing digital disruption in their industry to make their manufacturing operations more efficient. Innovations in robotics, Artificial Intelligence, Machine Learning, Big data, automation, and many others, contribute to the current industrial revolution

-

Delivery and logistics

Logistics and delivery are other areas that companies can and should be smart about. The pressure to cut costs is forcing companies to be more creative with their logistics operations. Also, this is one of the main areas where companies can go green. Making the entire supply chain more sustainable is a major challenge across industries, and logistics is one big chunk of the supply chain that presents businesses with this opportunity. Surprisingly, a green supply chain and sustainable logistics operations are proven to cut costs for the company too!

-

Returning

As the name suggests, it is the movement of goods that are sent back to the manufacturer either by an end user or a distributor. There could be a multitude of reasons for this, but the most probable one is the product being defective. But companies have the opportunity to extract valuable insights from this “return” behavior of the users. As a data analytics services provider, we have helped companies dissect complex consumer behavior to help them craft custom strategies for their buyer personas. By closely monitoring the product/service return patterns, companies can make critical business decisions, including reengineering and R&D.

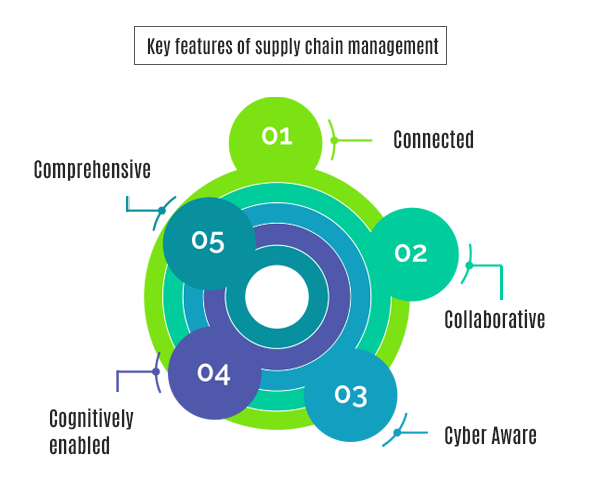

Key features of supply chain management

As companies adopt new supply chain technologies and techniques, it is important to create a framework of the key features of supply chain management.

- Connected

- Collaborative

- Cyber Aware

- Cognitively enabled

- Comprehensive

How digitalizing supply chain management can help brands capitalize on opportunities?

The goal of digitalizing supply chain management is to help businesses track and monitor the efforts and assets involved in their whole business process. For many brands, scaling up is to streamline their supply chain models. Being one of the major league digital transformation services providers in the global market, we helped an international beverages company to expand its brand’s footing in a completely alien market. While coming up with strategies to make it happen, we identified that following traditional product flow and distribution systems is obstructing our client to capture value in the new market.

While we would suggest end-to-end digitalization of their supply chain, it was practically not feasible as a sudden change would disrupt the existing business operations of our client. So, we adopted partial digitalization that’s more flexible and enables the client to gradually but steadily adjust to the new system.

In the end, our client was able to create a dynamic business ecosystem that positioned them as one of the top players in that geography. Despite the target market being immune to new brands, our client was able to expand its operations in a matter of months. Our data-infused product flow system accelerated our client’s capability to extract actionable insights regarding the people, place, product, consumer behavior, and many other nuances of the market.

Frequently Asked Questions

Get inspired!

Subscribe to our newsletter and get updates on how to navigate through disruption and make digital work for your business!